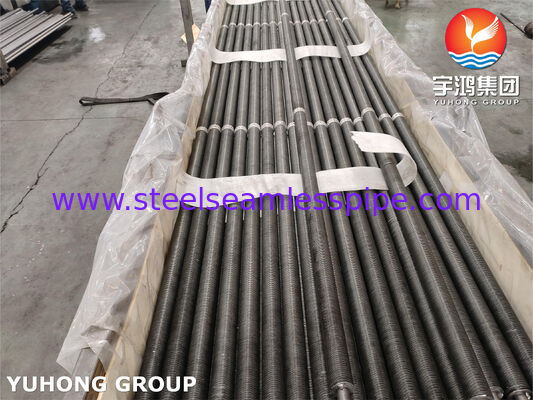

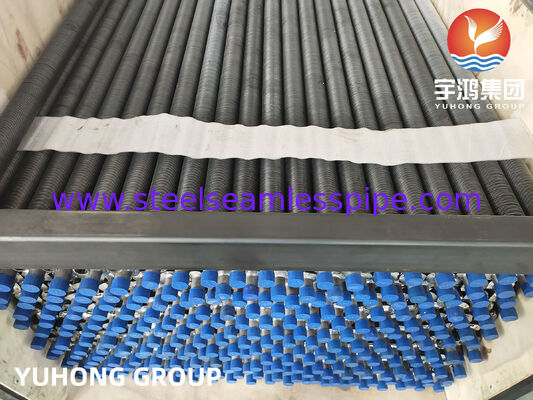

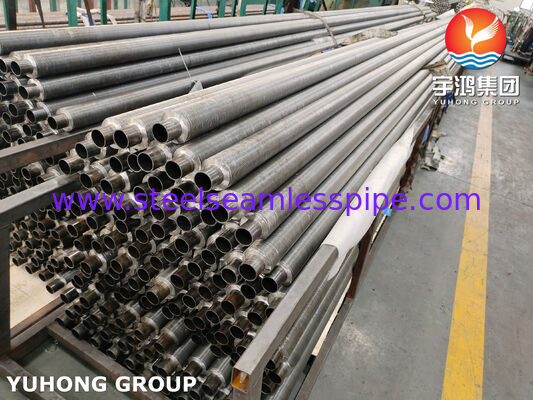

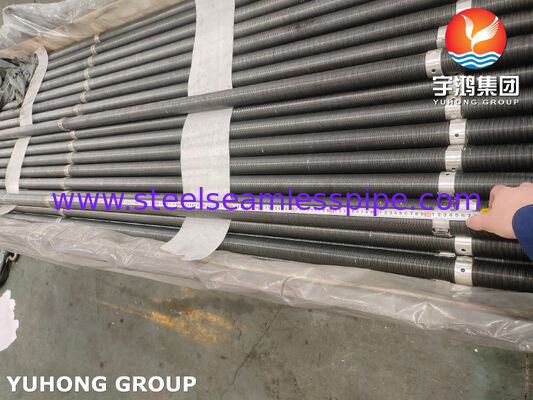

Yuhong Holding Group Co., LTD

Để lại lời nhắn

Chúng tôi sẽ gọi lại cho bạn sớm!

Gửi đi

Ông

- Ông

- Bà

được

Chúng tôi sẽ gọi lại cho bạn sớm!

được

Để lại lời nhắn

Chúng tôi sẽ gọi lại cho bạn sớm!

Gửi đi