1. Vật liệu ống cơ bản: A106 Gr.B

Tiêu chuẩn: ASTM A106 / ASME SA106.

Loại: Ống thép carbon liền mạch.

Cấp: B (Độ bền kéo/chảy trung bình).

Đặc tính:

- Độ bền nhiệt độ cao tốt (lên đến ~450°C / 840°F).

- Khả năng hàn và tạo hình tốt.

- Tiết kiệm chi phí.

- Hạn chế: Dễ bị ăn mòn (gỉ) và oxy hóa (tạo vảy) ở nhiệt độ cao nếu không có biện pháp bảo vệ; không thích hợp cho môi trường ăn mòn trừ khi được bọc hoặc phủ.

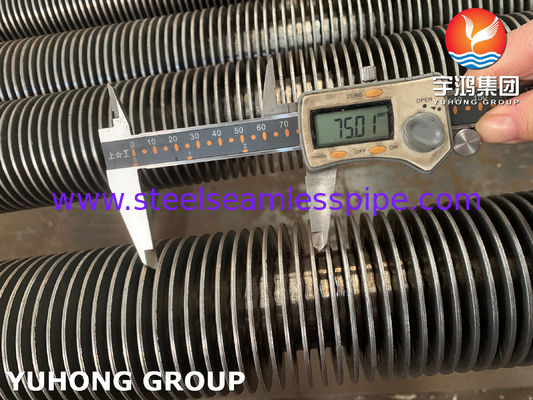

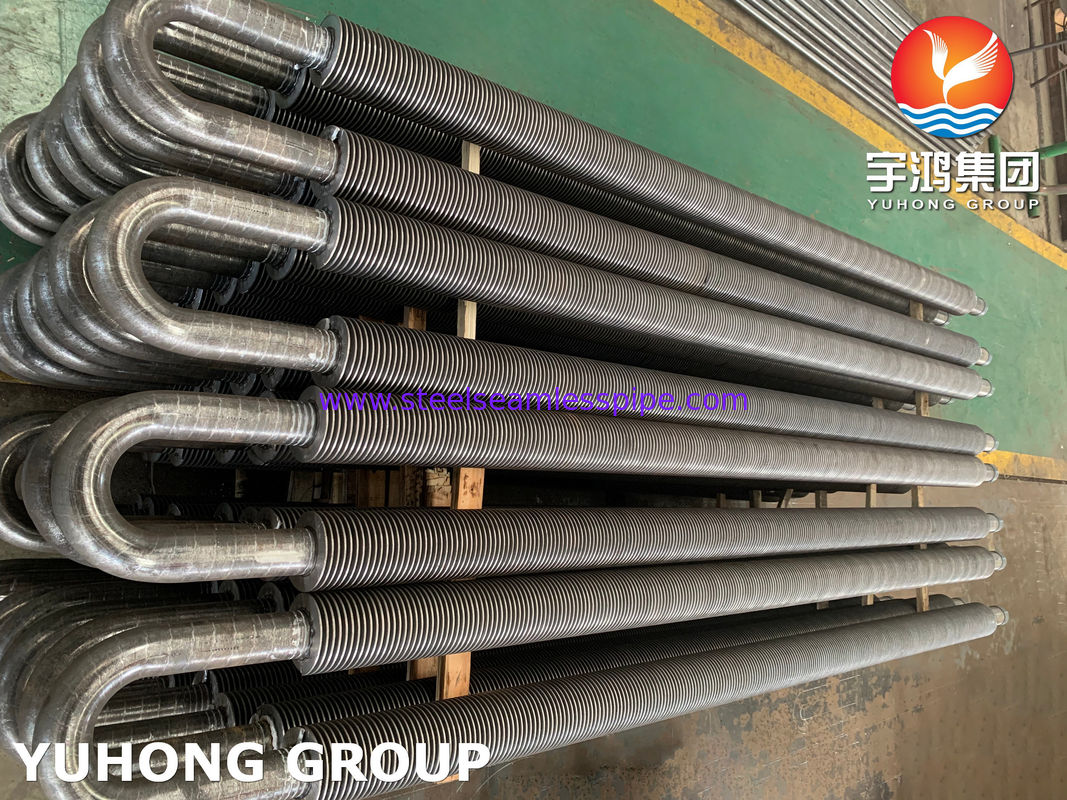

2. Loại cánh tản nhiệt: Cánh tản nhiệt đặc

Cấu tạo:Cánh tản nhiệt được làm từ các dải vật liệu đặc (thường là thép carbon hoặc đôi khi là thép không gỉ để chống ăn mòn).

Gắn kết: Các cánh tản nhiệt được hàn liên tục (thường là hàn điện trở, LFW hoặc HFW) dọc theo chân của chúng vào bề mặt bên ngoài của ống cơ bản. Điều này tạo ra một liên kết luyện kim chắc chắn.

Ưu điểm:

Truyền nhiệt tuyệt vời: Tiếp xúc trực tiếp kim loại với kim loại mang lại điện trở nhiệt rất thấp.

Độ bền cơ học cao & Độ bền: Chống rung, xói mòn và hư hỏng vật lý.

Tốt cho nhiệt độ cao: Mối nối hàn duy trì tính toàn vẹn ở nhiệt độ cao.

Dễ làm sạch: Bề mặt nhẵn giúp dễ dàng làm sạch/quét hơn so với cánh tản nhiệt nhúng.

Nhược điểm:Chi phí cao hơn so với cánh tản nhiệt đùn hoặc nhúng.

Áp suất giảm cao hơn một chút so với cánh tản nhiệt có cấu hình thấp hơn.

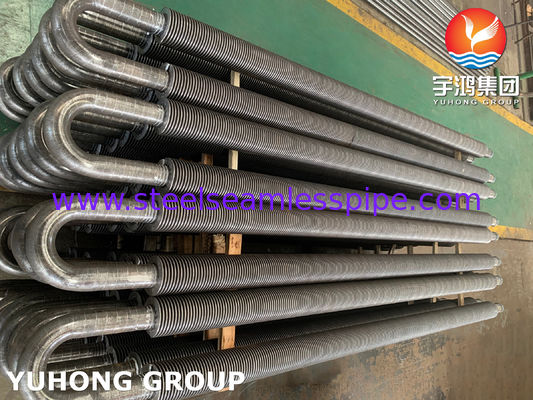

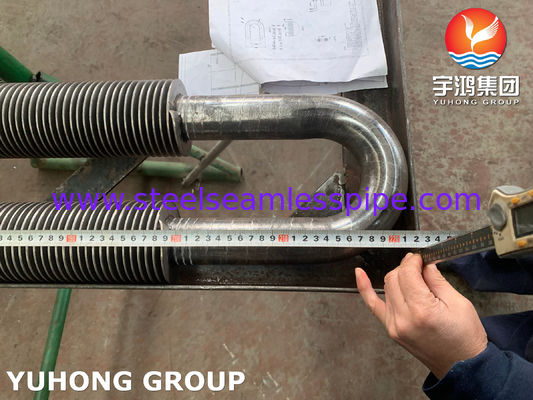

3. Cấu hình ống tổng thể: Kiểu U

Hình dạng: Ống có cánh tản nhiệt được uốn thành hình chữ "U" chặt chẽ (uốn 180 độ).

Mục đích:

Giãn nở nhiệt: Cho phép bó ống giãn nở và co lại tự do bên trong vỏ của bộ trao đổi nhiệt mà không gây ứng suất quá mức lên tấm ống hoặc ống.

Tháo bó ống: Tạo điều kiện kéo toàn bộ bó ống ra khỏi vỏ để kiểm tra, làm sạch hoặc bảo trì.

Tấm ống đơn: Chỉ yêu cầu một tấm ống ở đầu thẳng, đơn giản hóa thiết kế hộp đầu/kênh ở đầu đó.

Cấu tạo: Quá trình uốn xảy ra sau khi các cánh tản nhiệt được gắn vào. Cần có thiết bị và kỹ thuật uốn cẩn thận để tránh làm hỏng các cánh tản nhiệt hoặc làm ảnh hưởng đến liên kết cánh tản nhiệt ở đỉnh uốn.

4. Tóm tắt & Ứng dụng điển hình:

Ống cánh tản nhiệt đặc kiểu U A106 Gr.B là một bộ phận truyền nhiệt chắc chắn, hiệu suất cao được thiết kế cho các ứng dụng nhiệt độ cao đòi hỏi sự thích ứng giãn nở nhiệt và độ bền là rất quan trọng. Các tính năng cốt lõi của nó là:

Đế thép carbon nhiệt độ cao: Để đảm bảo tính toàn vẹn cấu trúc dưới nhiệt và áp suất.

Cánh tản nhiệt hàn đặc bền: Để truyền nhiệt hiệu quả và đáng tin cậy cho không khí/khí.

Cấu hình uốn chữ U: Để giãn nở nhiệt không ứng suất và bảo trì dễ dàng.

Các ứng dụng phổ biến:

Máy phát điện hơi thu hồi nhiệt (HRSG): Các phần tiết kiệm, bay hơi và quá nhiệt thu hồi nhiệt từ khí thải tuabin khí.

Bộ gia nhiệt & Lò nung quy trình: Các phần đối lưu truyền nhiệt từ khí thải vào chất lỏng quy trình.

Lò hơi thu hồi nhiệt thải: Thu hồi nhiệt từ các dòng quy trình nhiệt độ cao.

Bộ gia nhiệt/Bộ gia nhiệt trước không khí: Gia nhiệt không khí đốt bằng khí thải.

Bó ống cánh tản nhiệt trong bộ trao đổi vỏ và ống: Nơi khí ở phía vỏ và giãn nở nhiệt là đáng kể.

Các cân nhắc chính:

Ăn mòn: A106 Gr.B yêu cầu bảo vệ (ví dụ: lớp phủ như nhôm hóa, tạo cánh tản nhiệt bằng thép không gỉ, hoạt động trong khí khô/không ăn mòn) trong môi trường có độ ẩm, axit hoặc lưu huỳnh.

Oxy hóa: Sẽ tạo vảy ở nhiệt độ cao; cần xem xét cho hiệu suất lâu dài.

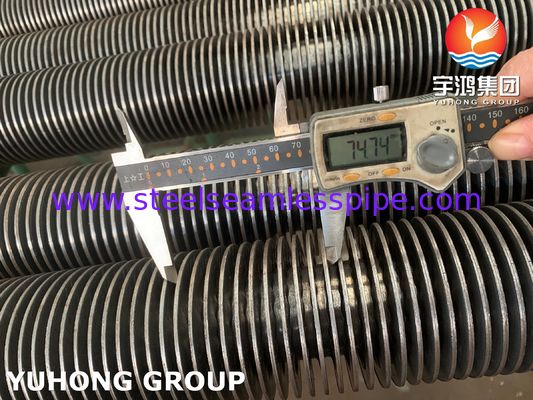

Mật độ cánh tản nhiệt: Số lượng cánh tản nhiệt trên inch/mét được chọn dựa trên độ sạch của khí (khả năng bám bẩn) và truyền nhiệt yêu cầu so với giảm áp suất.

Bán kính uốn: Độ chặt của uốn chữ U là rất quan trọng và được xác định bởi thiết kế bộ trao đổi nhiệt và đường kính ống.